Where does recycled leather come from?

Recycled leather is produced from waste leather — whether offcuts from the leather tanning industry, scraps from fashion production, or discarded consumer products such as old bags and shoes.

Although it’s derived from a natural product, traditional virgin leather can have a heavy environmental cost due to chemical processing. These chemicals can be harmful when leather breaks down, posing long-term issues for landfill and ecosystems.

By contrast, recycled leather aims to close the loop. It keeps valuable materials in circulation and supports a circular economy that minimises waste and environmental harm.

How is recycled leather produced?

The production of recycled leather is both innovative and efficient. Here’s a quick breakdown of the process:

- Leather cut-offs, waste, and scraps are collected, shredded, dried and ground into fine granules.

- These granules are mixed with water to form a pulp, which is dried and ground again.

- The pulp is stretched into a thin tape with leather-like characteristics.

- It is then pressed, compacted and dried in an oven for 8 to 16 hours to create a solid sheet.

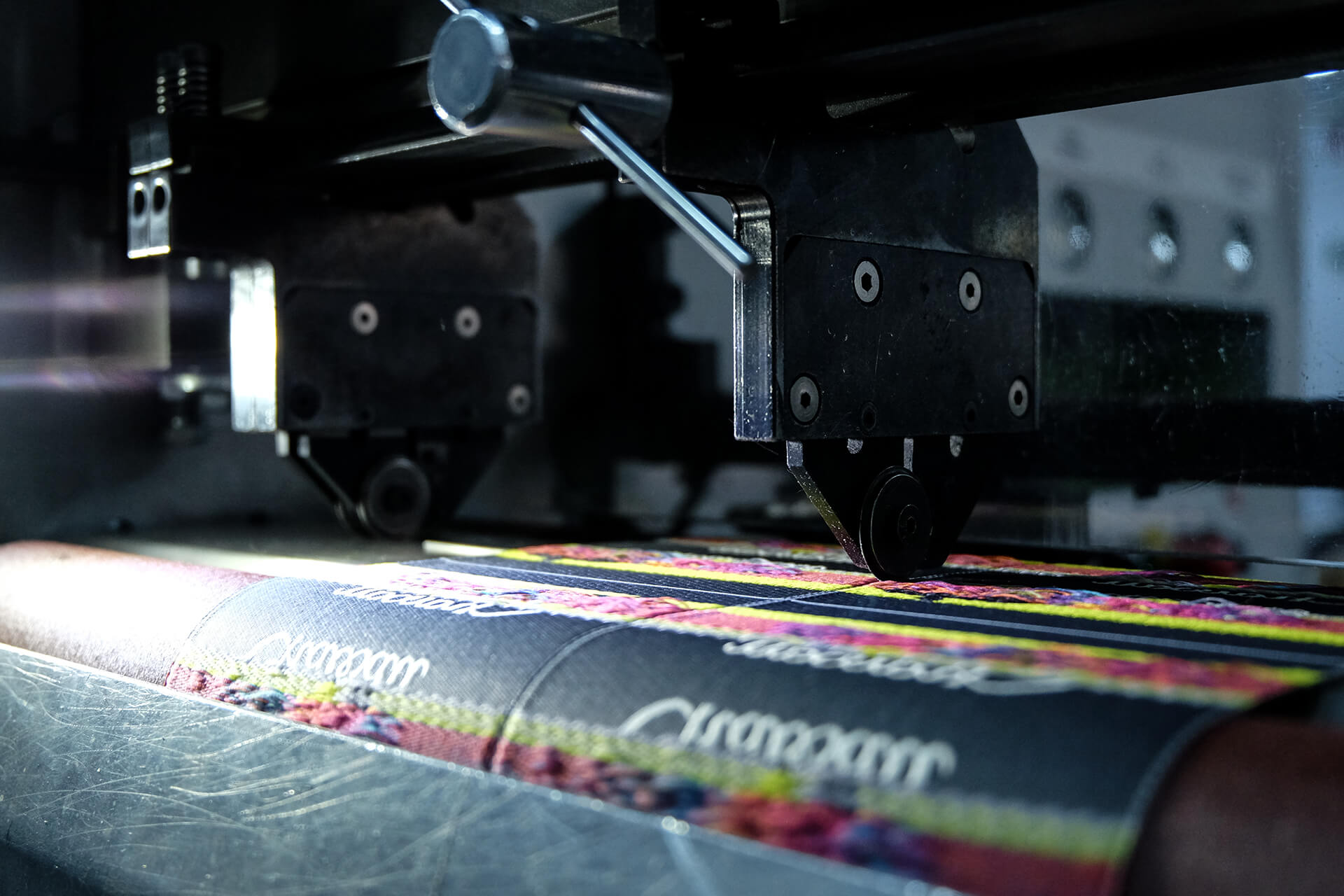

Finally, the recycled leather sheets are coloured, textured and finished with treatments to match specific design or branding needs.

This process results in a durable, adaptable material that can replicate many of the aesthetic qualities of real leather — without the environmental toll.

What are the pros and cons of recycled leather?

While recycled leather has properties similar to virgin leather, it has been processed and won’t be exactly the same. Recycled leather uses polymers and chemicals during production, which impacts the material‘s overall performance.

The pros of recycled leather

- Reduces waste by repurposing materials that would otherwise end up in landfill.

- Supports a circular economy and more sustainable production cycles.

- Offers greater creative flexibility — with a broader range of colours, textures and finishes than virgin leather.

- Cost-effective due to lower material and resource input.

- Naturally water-resistant, meaning it’s less prone to staining.

- Suitable for a wide range of branding applications, from trims to accessories.

The cons of recycled leather

- Less durable than full-grain virgin leather, especially in high-wear environments.

- More prone to cracking and peeling over time due to its thinner composition.

- Still involves synthetic binders, chemicals and water in the production process.

- Energy usage can be high during processing, depending on the manufacturer.

How can you incorporate recycled leather into your branding projects?

Looking to elevate your sustainability credentials while maintaining a premium feel? Recycled leather is a perfect fit for brands that want to combine eco-conscious values with a tactile, high-quality finish.

Here are just a few applications where recycled leather shines:

Woven or embossed badges

Branded patches for apparel

Zip pulls and keyrings

Hangtags and swing tickets

Luxury packaging trims

Whether you’re designing for retail, fashion or lifestyle products, recycled leather adds an elevated touch that tells a sustainability story your customers will connect with.